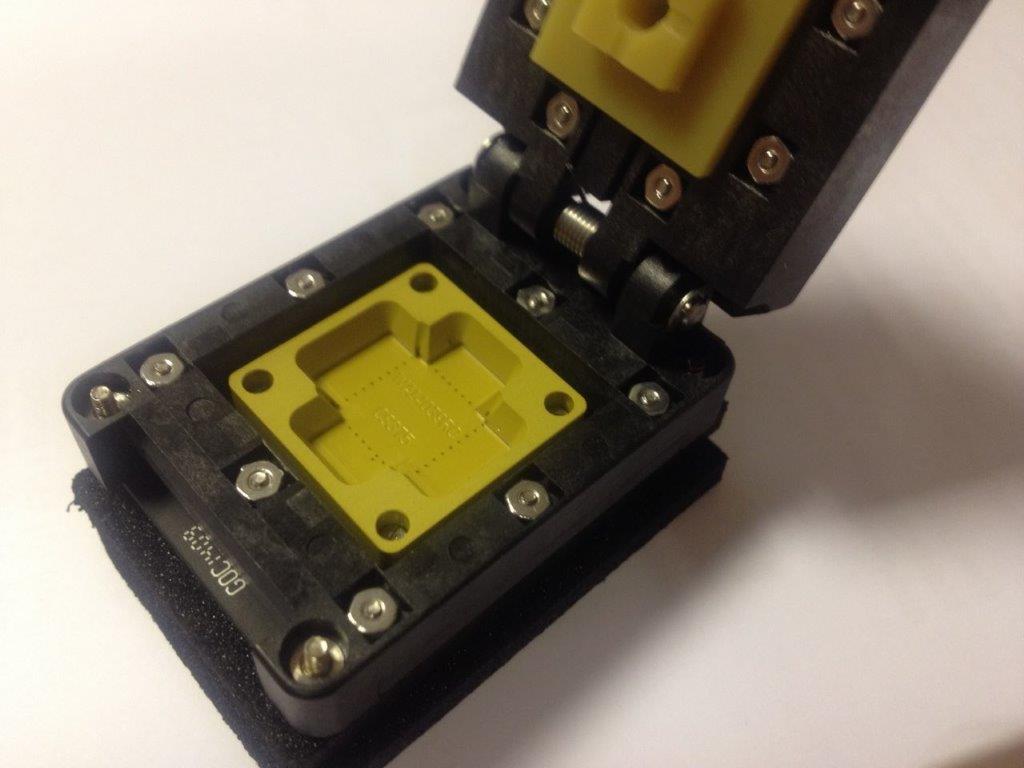

Winslow – Test sockets and Tackling Obsolescence in Component-Based Designs

Winslow designs and manufactures unique test socket and interconnect solutions for a broad range of package types and lead pitches. Their design team use state-of-the art computer-aided design tools, including 3D mechanical modelling, for the socket design. At this point they can supply the recommended footprint if this hasn’t already been determined by the target.

Winslow designs and manufactures unique test socket and interconnect solutions for a broad range of package types and lead pitches. Their design team use state-of-the art computer-aided design tools, including 3D mechanical modelling, for the socket design. At this point they can supply the recommended footprint if this hasn’t already been determined by the target.

Furthermore, Winslow possesses the design and manufacturing strengths to seamlessly integrate support-phase alternatives at component level. Design documentation undertakes to achieve protection from obsolescence into the future to ensure continued manufacturing capability is secure. Products include PMA ASIC, FPGA, intelligent LED and TO devices along with simple footprint converters and daughter boards.

Winslow offers:

- In-House Design and Manufacture to include DO254 for Civil Aerospace

- Rapid Manufacture of Custom Pin Sizes

- Adapters to Mitigate Component Obsolescence

- Adapters for Function Upgrades, Prototyping & Test

- Chip Carriers for Die Attach

- Re-creation of Character Specific Intelligent LEDs

- Firmware and retargeting of analog and digital ASICs into FPGA

- Custom and COTS Test Sockets to 0.3mm Pitch

- Custom Sockets

- Reverse Engineering of Obsolete Connectors and Hardware

- COTS Sockets, Connectors and Jermyn Semiconductor Hardware

- Footprint Conversion

- ASIC/FPGA Conversion

- Test sockets & interconnects

Winslow Adpatics ensures you keep building when component manufacturers stop.